NEW! Take a virtual visit into the LPP facilities ⇒ Click Here |

Instalações |

- A 100 m2 clean room

- 1 MW electric power

- 10 ton overhead crane

- DC power source of 750 kW

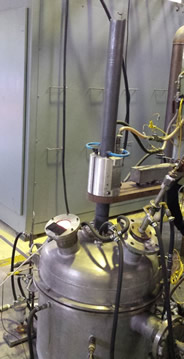

- A 3 m3 plasma tunnel

The LPP is located on dedicated buildings that sum up to 2000 m2, which includes:

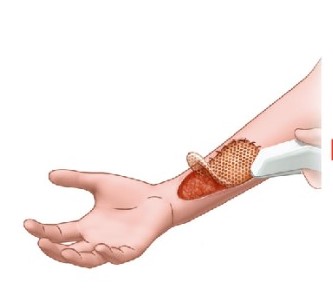

Cold Plasma Sector |

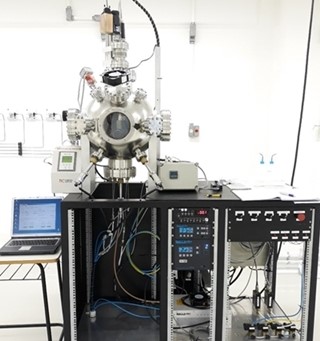

- Physical Vapor Deposition – PVD (Sputtering)

- Plasma-enhanced chemical vapor deposition – PECVD

- Reactive-ion etching – RIE

- Plasma nitriding and carburizing by DC and pulsed power source

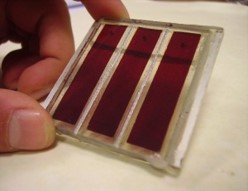

The Cold Plasmas Sector has a variety of reactors for the production of thin films and surface treatments of several materials using low pressure plasma processes, such as:

Among the main applications, we can mention implant coating, production of electrodes for third generation solar cells, and development of materials and sensors for aerospace.

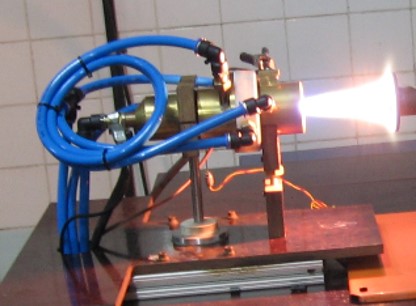

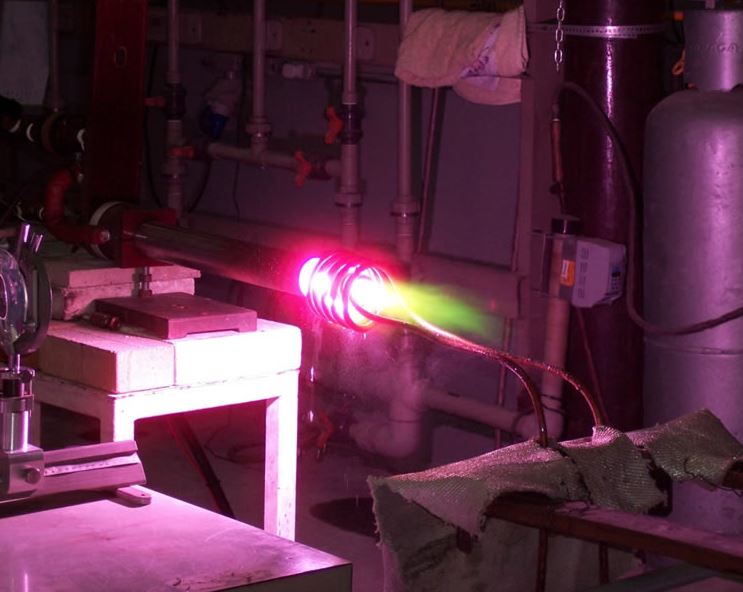

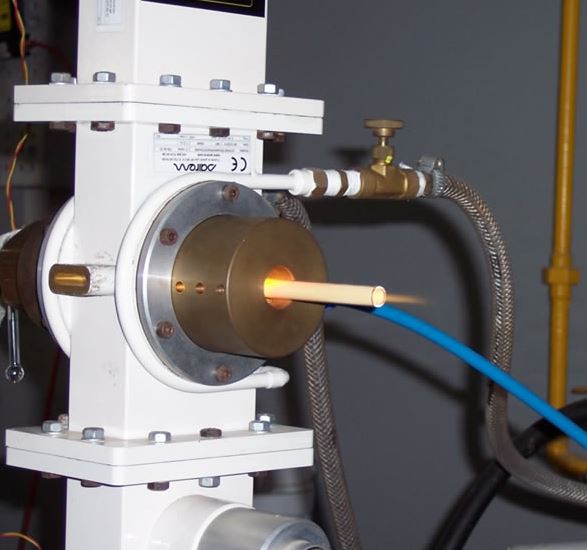

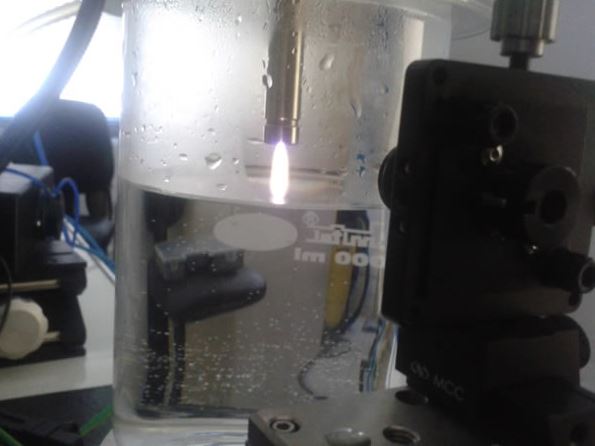

Thermal Plasmas Sector |

The ITA Plasmas and Processes Laboratory is one of the few in Brazil to master technologies that employ thermal plasma torches. The applications involve the deposition of thermal protection barriers by spraying refractory materials and ablation tests on thermal barrier materials. These processes aim at the development of materials for application in nozzles and thermal shields of vehicles reentering the atmosphere. In addition, the laboratory has knowledge on the treatment of waste through plasma gasification process, aiming at energy generation and metal recovery.

Optical Spectroscopy Sector |

The Optical Spectroscopy Sector has it’s main purpose to study cold and thermal plasmas which are luminous sources produced in laboratories through electrical discharges. Some plasmas are produced in the lab, the most important ones being low pressure plasmas in argon gas, nitrogen or a mixture of these. Other gases, such as oxygen and hydrogen, are incorporated into the electrical discharge for actinometric purposes or as optical probing elements. Plasmas at atmospheric pressure, such as hollow microcathode microplasmas and micro-jet in CC or RF mode are also produced and studied for surface modifications (corrosion, etching, DLC deposition) or for chemical analysis.

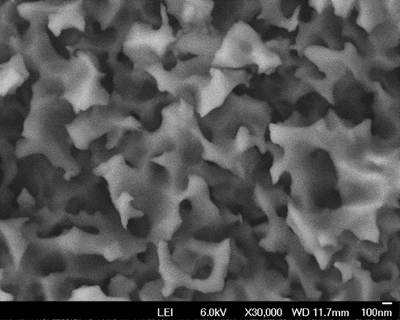

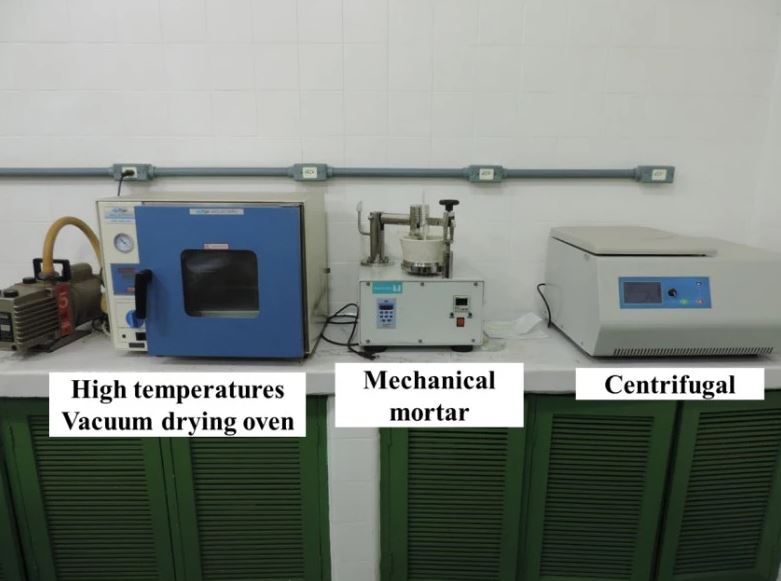

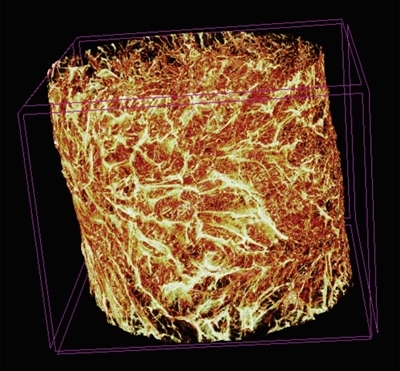

Nanotechnology Sector - LabNanoTec |

LabNanoTec has the ability to synthesize materials by conventional chemical and hydrothermal methods. It has knowledge of the technology for processing nanostructured materials for aerospace and other applications. It also develops effluent treatment by adsorption and sonocatalysis.

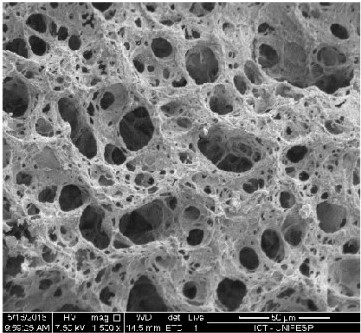

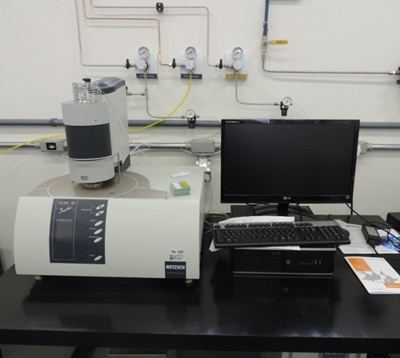

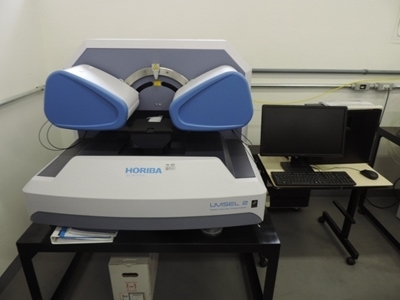

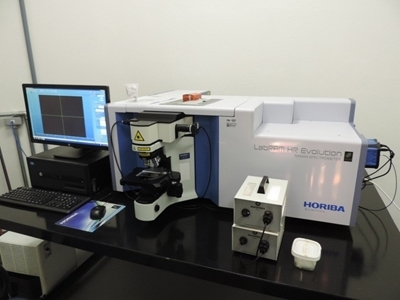

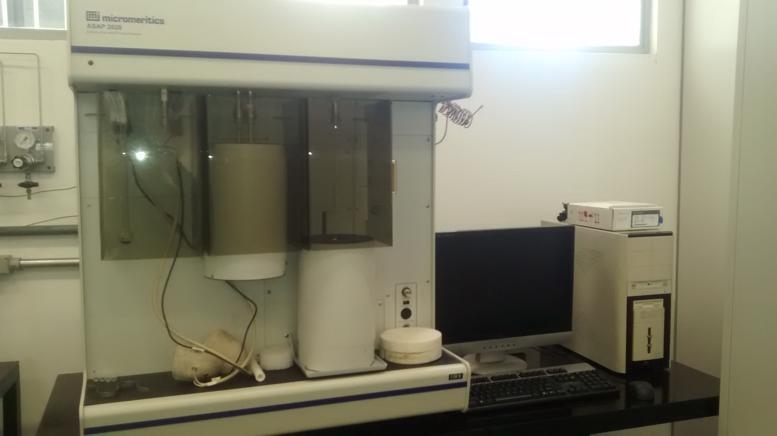

Materials Characterization Sector - LabMat |

-

X-Ray Diffractometer (XRD);

-

Raman Spectrometer;

-

Spectroscopic Ellipsometer;

-

Goniometer;

-

Profilometer;

-

Infrared Spectrophotometer (FTIR);

-

Atomic Force Microscope (AFM);

-

Differential Scanning Calorimeter (DSC);

-

Surface Area Analyzer (BET);

-

Four-Point Probe

LabMat centralizes important equipment for characterization of essential materials for the analysis of various types of samples from the ongoing research of the LPP. Among the available resources, we can list the following equipment:

More details related to the specific characteristics of the equipment, as well as regarding the access to the tecniques and equipments, can be found in the Collaborators tab.